Overview

By precisely defining cleaning agents, pressure, temperatures, and times, a reproducible process is established.

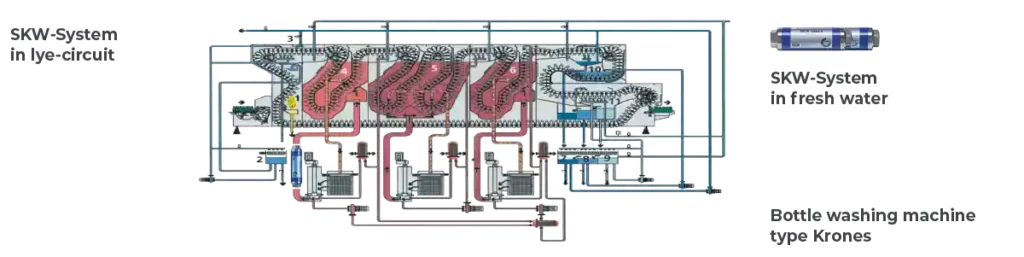

The SKW System provides advantages in lye conditioning through increased intensity and improved distribution accuracy.

Advantages

- Clear lye, no foam formation

- Prevention of lye scale on the walls of the lye tank and in the piping systems

- Extended service life and durability of the system

- Maintenance-free

A contribution to water protection at Löwenbräu AG Munich

In February 1993, an SKW® system was installed in the riser pipe for the overflow of the bottle washing machine, type Krones Zierk. An SKW 5000 with a 2 1/2 inch connection and a treatment capacity of 35 m³/h was used. This ensures the treatment of the entire lye within one hour. The use of the SKW® system results in a significant reduction of surface tension.

As a result, it is possible to reduce the additive input into the lye by up to 60 percent. Another resulting effect is the significantly improved sedimentation behavior of the lye. Up to 25 percent more settleable substances due to surface tension reduction represent an important step toward high-quality, long-lasting lye.

The long-lasting lye is both ecologically and economically beneficial, says brewmaster Klaus Link, since the quality of the lye remains constant despite the considerably reduced additive usage. The SKW® system is part of an advanced concept by Löwenbräu AG, making a significant contribution to water protection.

(Source: Brauindustrie 6/94)